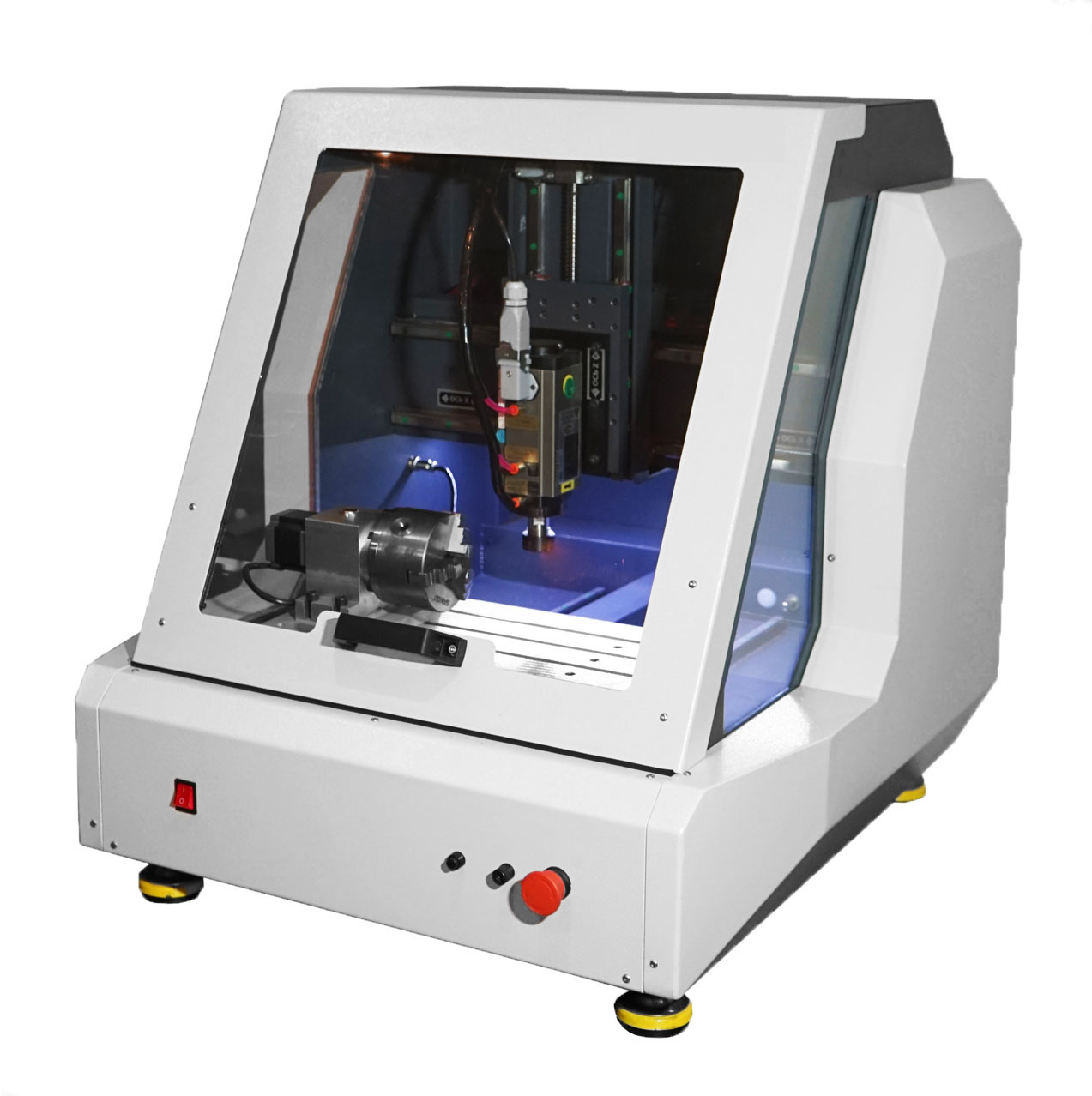

SX-40PC

3 axis high performance machining

- Stable design with a work table made of material B95-St

- Mounting the workpiece to the desktop T-mod. groove 11 x 19 mm.

- The maximum speed of movement is 150 mm / sec.

- The machine bed and stand are made in accordance with GOST 12.2.009-099 from St3 / St45 materials up to 20.0 mm thick, annealed, vibration-stress relieved, landing on the bed are made by planing, milling and grinding “in one set”, the drive to the desktop along the Y axis.

Tool Store

- Automatic pneumatic tool change, number of cutters up to 5 units.

- Convenient access to equipment in front.

Spindles

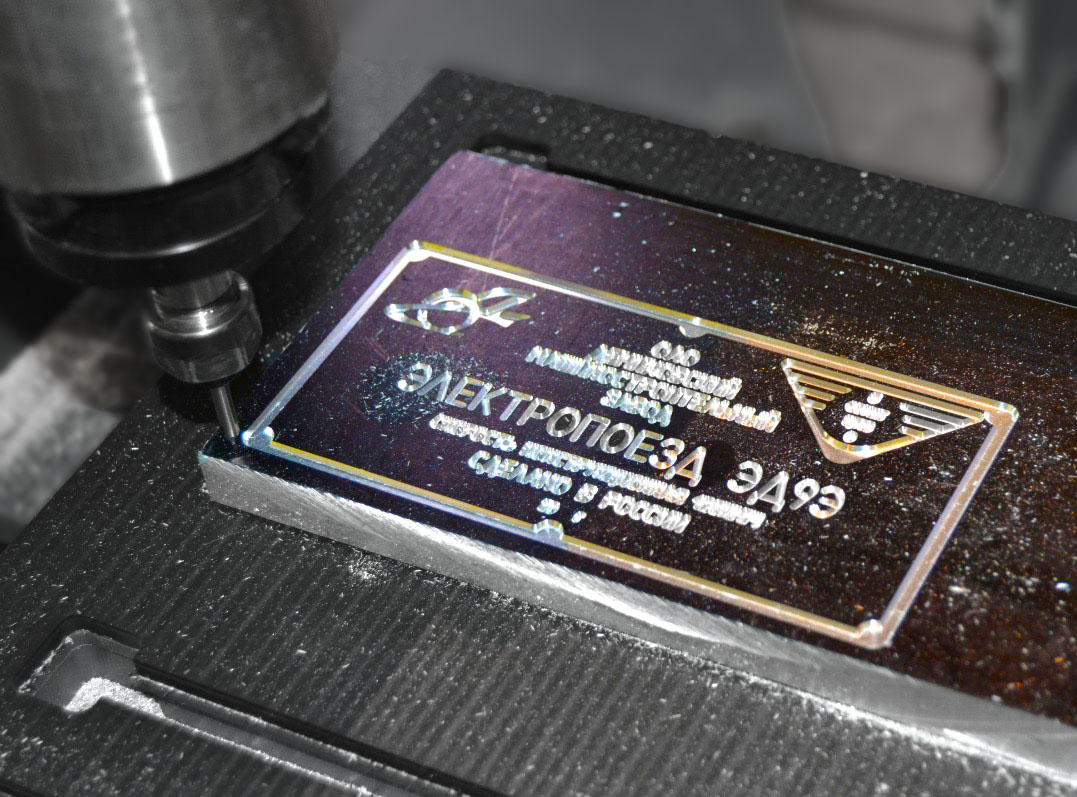

- 1.5 kW spindle ER20, 24000 rpm, liquid cooling.

- 0.4 kW spindle, max. cutter diameter 3.0 mm, 220 V., 10.000 - 100.000 vol. min., 1333 Hz, automatic tool change, the spindle takes the cutting tool by the shank of the cutter (optional).

- Spindle SGC 2.2 kW ER20, 24000 rpm, liquid cooling (optional).

Accuracy

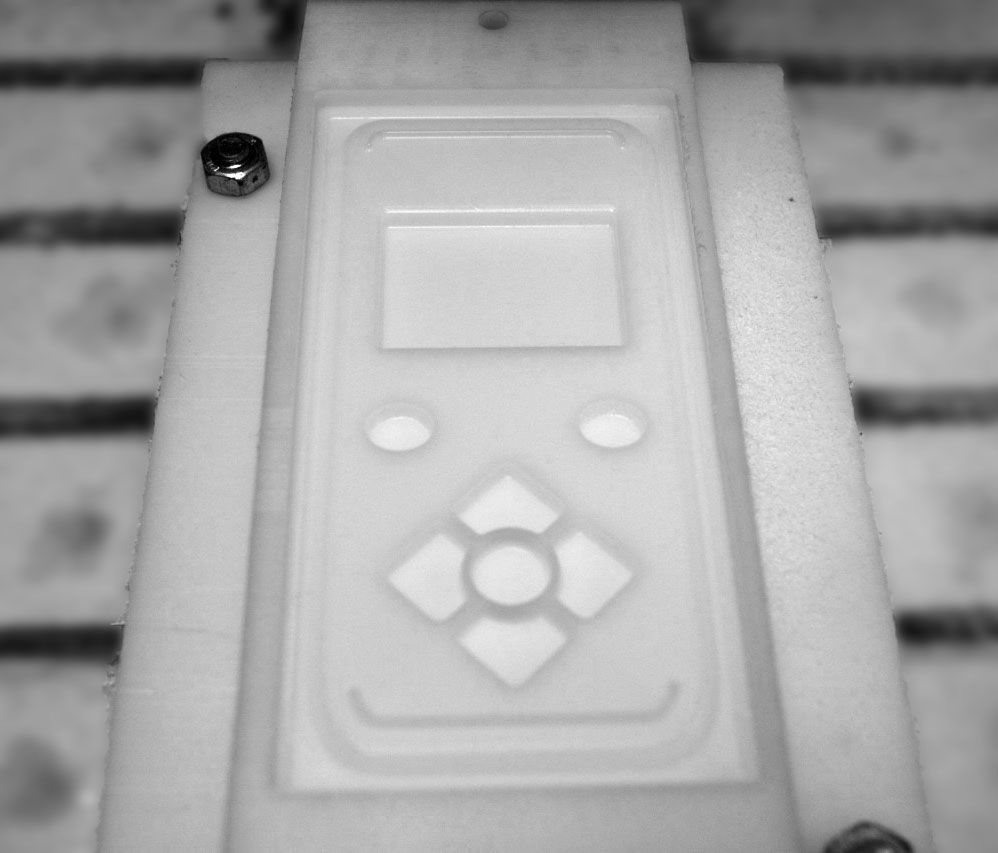

- Stable design with a work table made of material B95-St

- Guides HGR15 HiWin

- XY DRIVE ball screw 1605

- Z Ball screw drive 1605

- DRIVE SERVO MOTORS

- Repeatability 0.052 mm.

- Rack LinuxCNC.

- Set of collets.

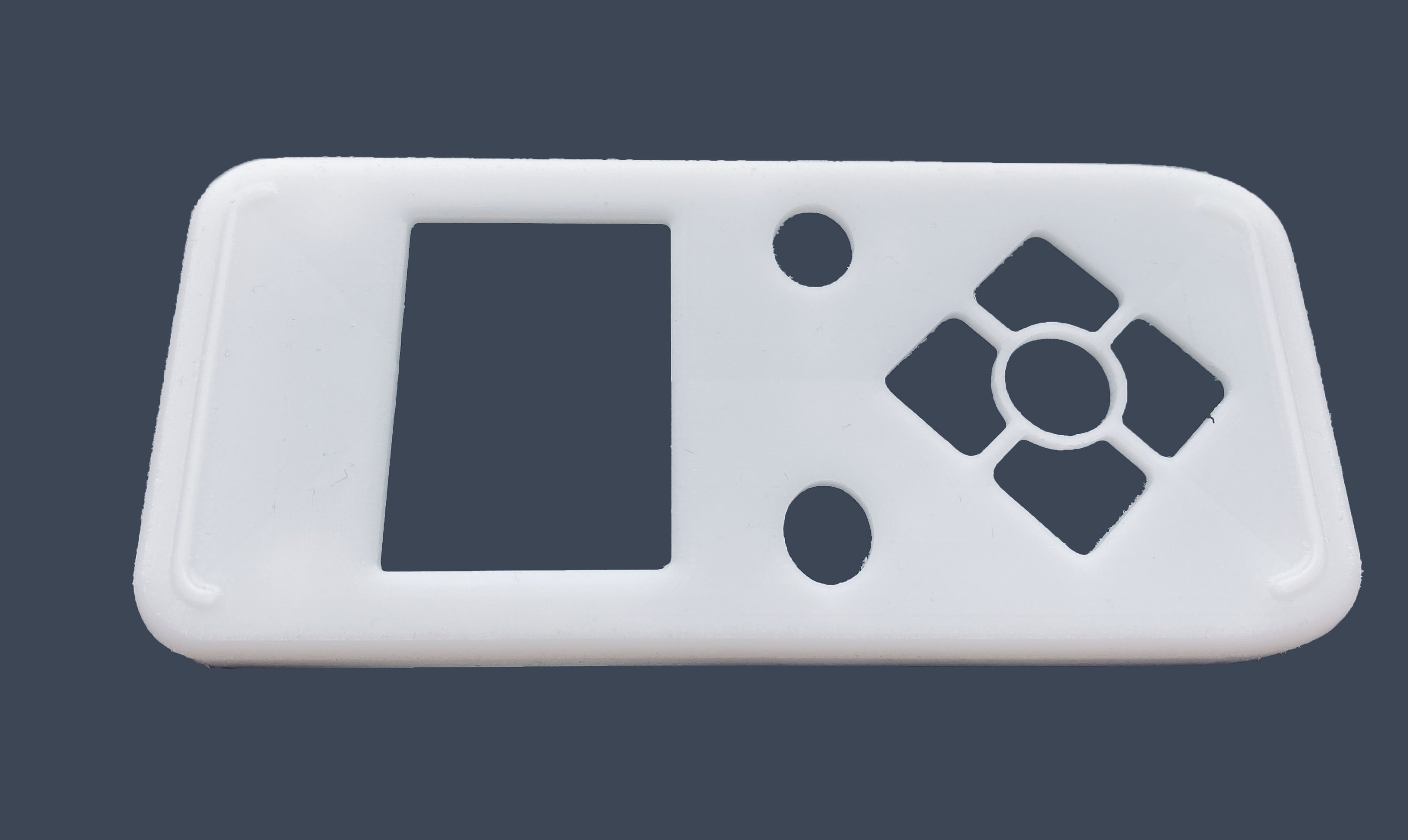

- Set of universal carbide cutters.

- Devices for attaching the workpiece to the desktop.

- Machine zero sensors (Home) on the X, Y, Z axes.

- Installation sensor Z coordinates TOOL SENSOR.

- Keys for installation \ removal of the working tool.

- Licensed P.O .: Geometric modeling and processing programming system for CNC machines GeMMa-3D Proma1x1.

- Additional illumination of the "processing zone" of the machine.

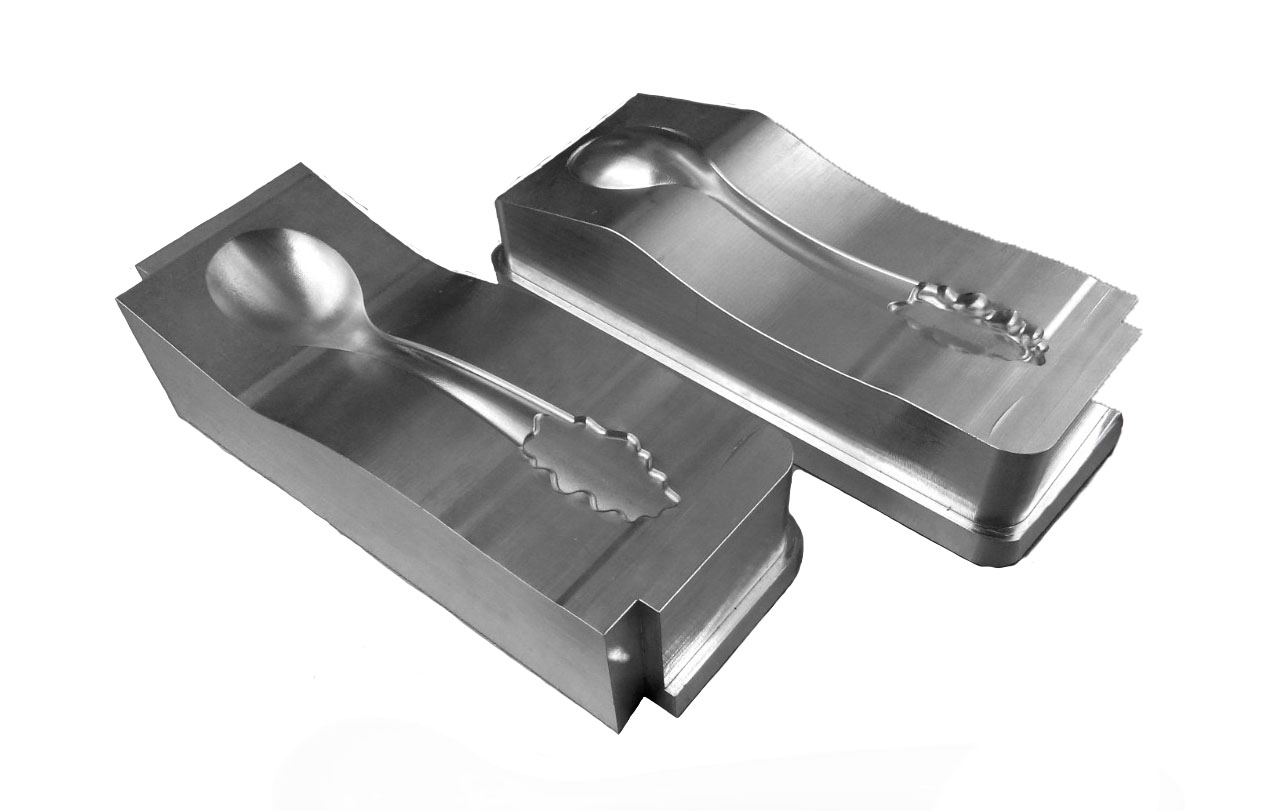

Created specifically for the electronic, dental and military industries to perform complex and high-precision dry and wet precision processing of materials with a hardness of up to 60 HRC with built-in LinuxCNC CNC control, with the ability to download programs via the Enternet network or via USB flash memory. Direct feedback, high speed of processing, movement, precision manufacturing of products from materials: zirconium, presceramics, wax, PMMA, graphite, composite, Ti, CrCo.

Automation is a key prerequisite for digital production. Each machine of ELBRAS LLC can be turned into a flexible production system by retrofitting with standard automation equipment or automation tools according to customer specifications:

- Fourth rotary axis A, rotation angle + -360 gr. Three-jaw chuck Ø125 mm. . + tailstock.

- Licensed P.O .: Geometric modeling and processing programming system for CNC machines GeMMa-4D Professional 1x1 + tech. Support

- Automatic pneumatic tool change, the number of cutters up to 15 units;

- Preparation for aspiration.

The LinuxCNC stand is a CNC device based on the GNU Linux operating system designed for comprehensive and efficient engraving, drilling and milling group solutions. This is a device that allows you to generate steps during programming in the case of control type STEP-DIR-ENABLE and supports working with industrial cards with hardware processing of G-code.

| Clearance | |

|---|---|

| Max. X-axis travel | 15,8 in |

| Max. Y-axis travel | 11,8 in |

| Max. Z-axis travel | 6,9 in |

| Table dimensions | |

| Max. table load | 55 lbs |

| Table length | 15,8 in. |

| Table width | 11,8 in. |

| Volume | |

| Machine length | 29,7 in. |

| Machine width | 32,5 in. |

| Machine height | 30,1 in. |

| Total weight | |

| Total weight | 540 lbs |

| AC Requirements | |

| Mains voltage | 220 V |

| AC frequency | 50 Hz |