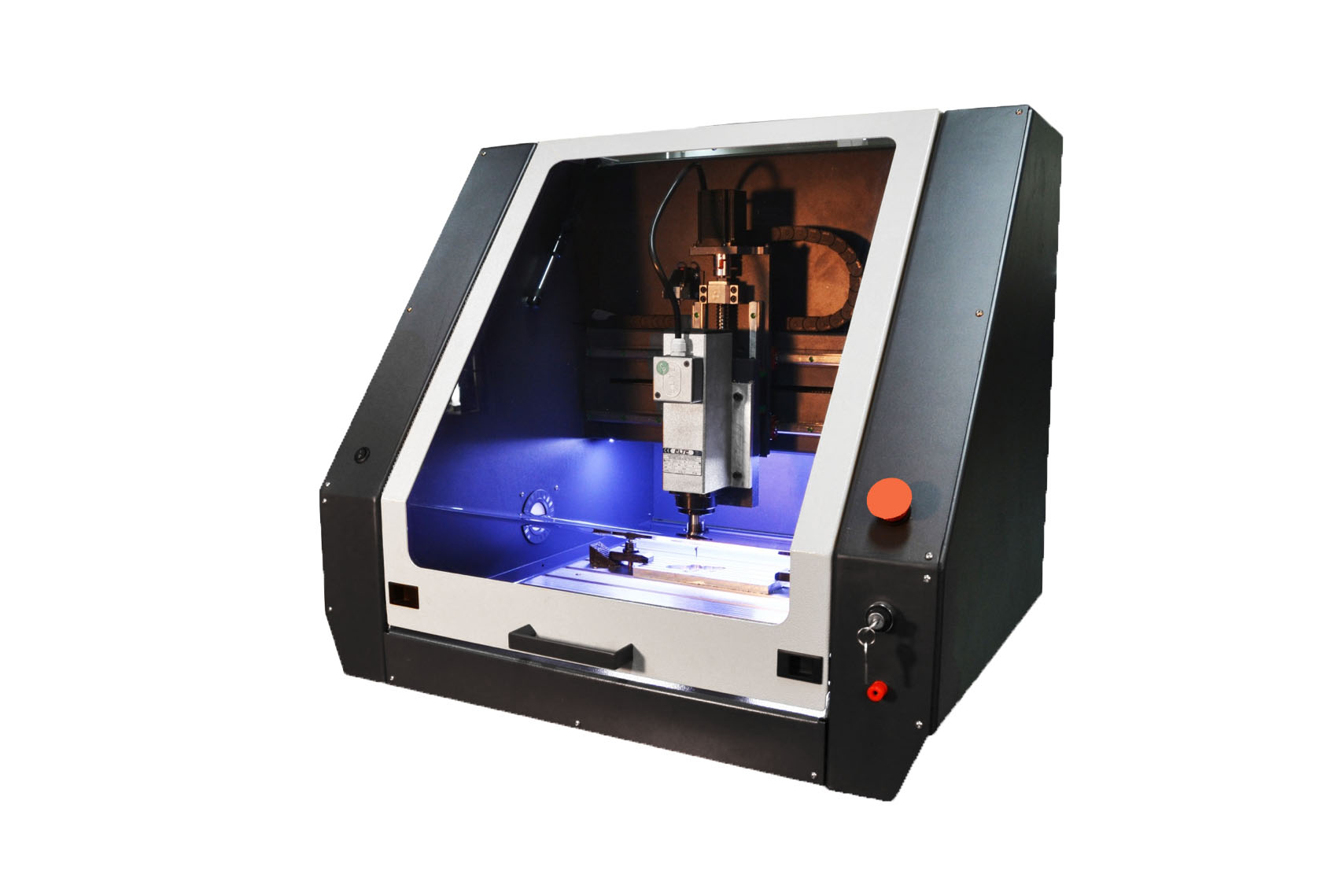

AX-40CPC

3 axis high performance machining

- Stable design with a work table made of St3 material

- Mounting the workpiece to the desktop T-mod. groove 11 x 19 mm.

- The maximum speed of movement is 35 mm / sec.

- The machine bed and stand are made in accordance with GOST 12.2.009-099 from St3 / St45 materials up to 10.0 mm thick, annealed, vibration-stress relieved, landing on the bed are made by planing, milling and grinding “in one set”.

Spindles

- Spindle SGC 800 W, ER 11, 3.000 - 24.000 rpm. min (optionally).

- Spindle ELTE TMPE2 9 / 2V 800 W, ER 20, 24.000 rpm min (optionally).

- Spindle HSD MT1055 1300 W, ER 20, 24.000 rpm min (optionally).

Accuracy

- Stable design with a work table made of St3 material.

- Guides HGR15 HiWin

- XY DRIVE ball screw 1605

- Z Ball screw drive 1605

- DRIVE SERVO MOTORS

- Repeatability 0.052 mm.

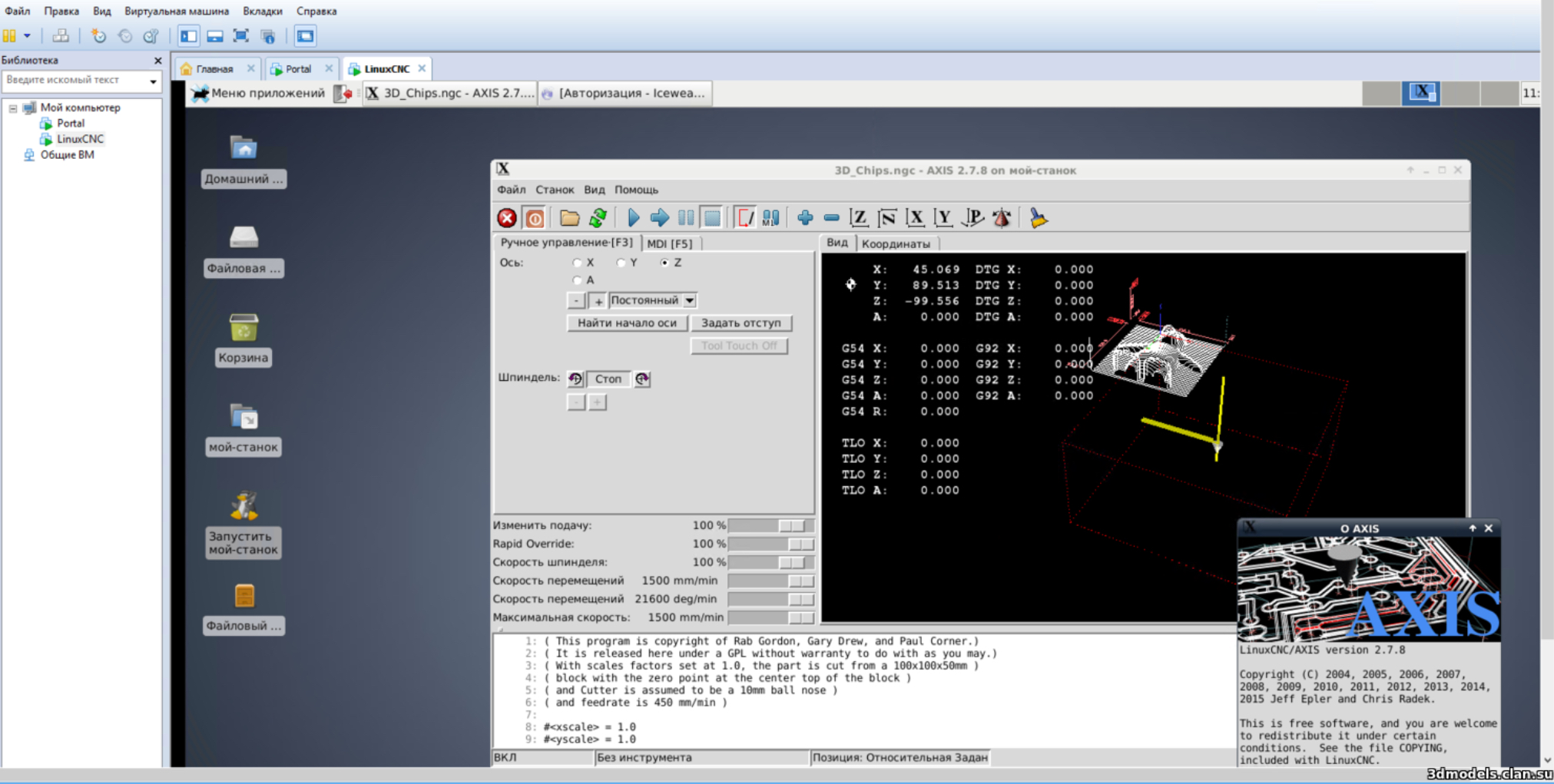

- CNC machine operating system: Linux OS

- Kress spindle collets 1050W 3.175, 8.0 mm

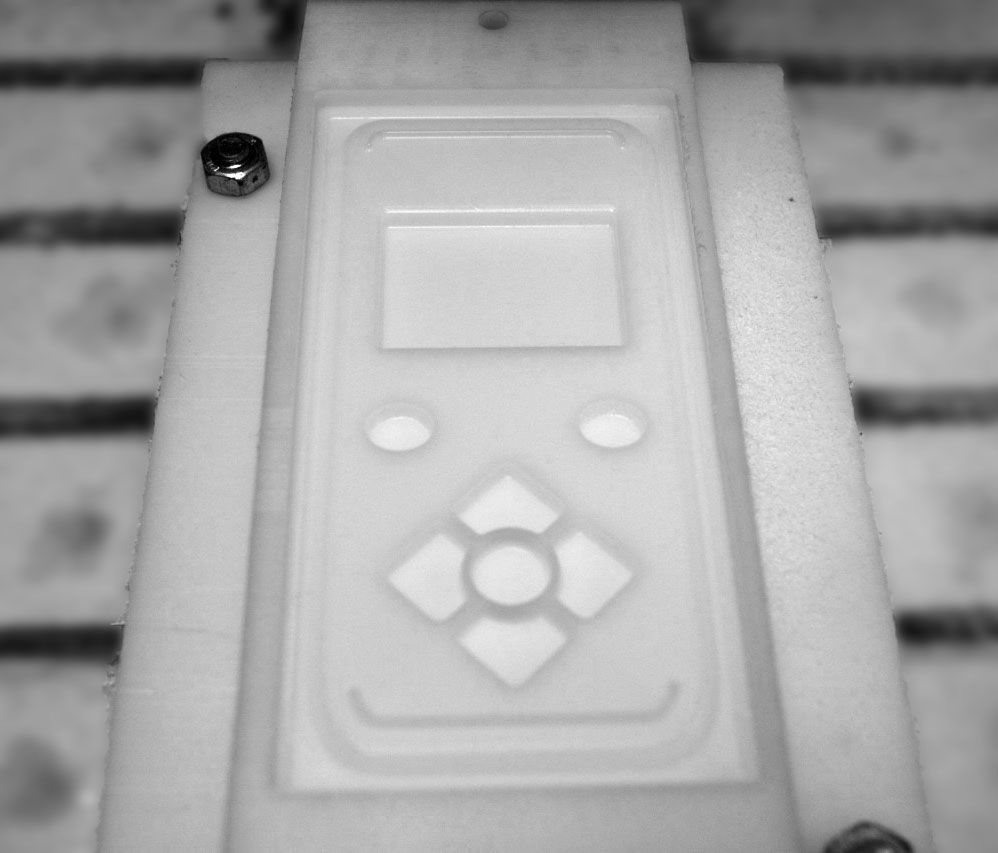

- Set of universal carbide milling cutters with 3.175mm shank

- Devices for attaching the workpiece to the desktop.

- Machine zero sensors (Home) on the X, Y, Z axes.

- Keys for installation \ removal of the working tool.

- Additional illumination of the "processing zone" of the machine.

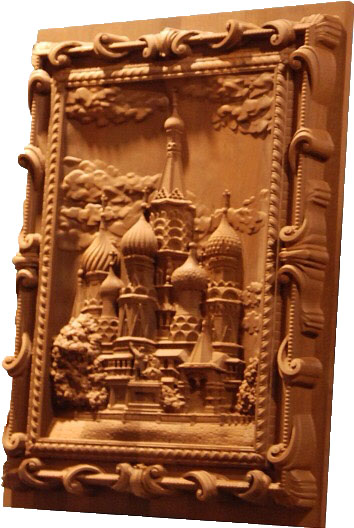

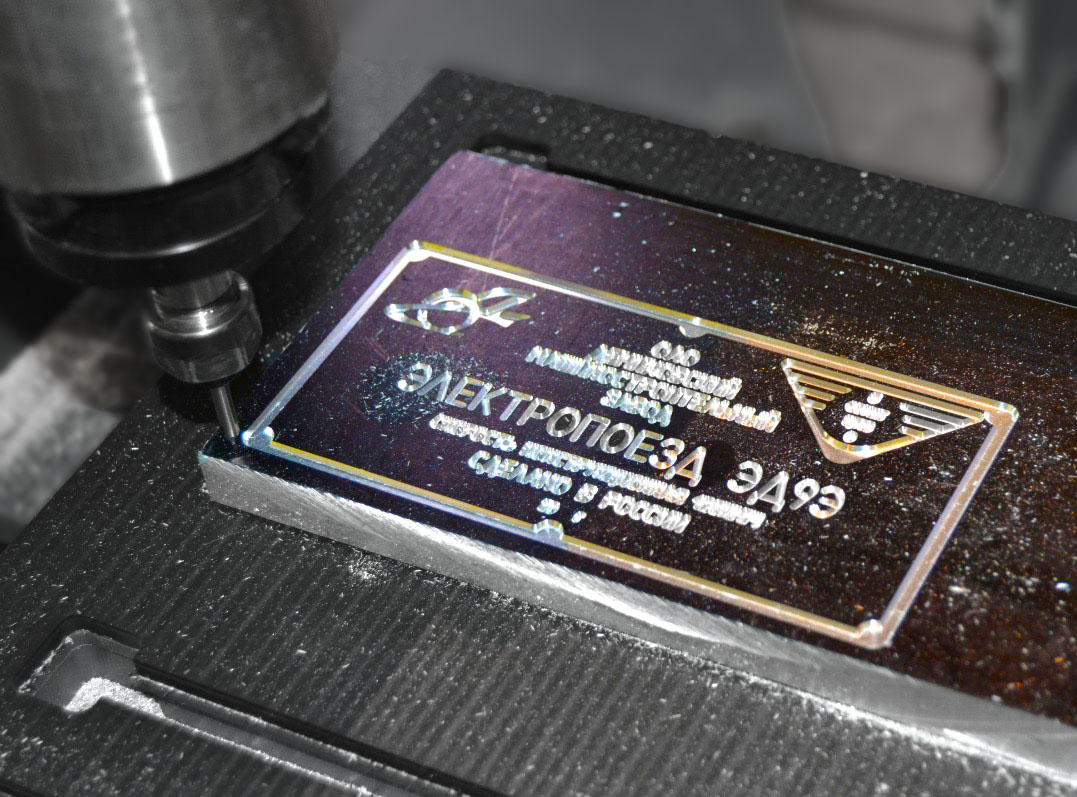

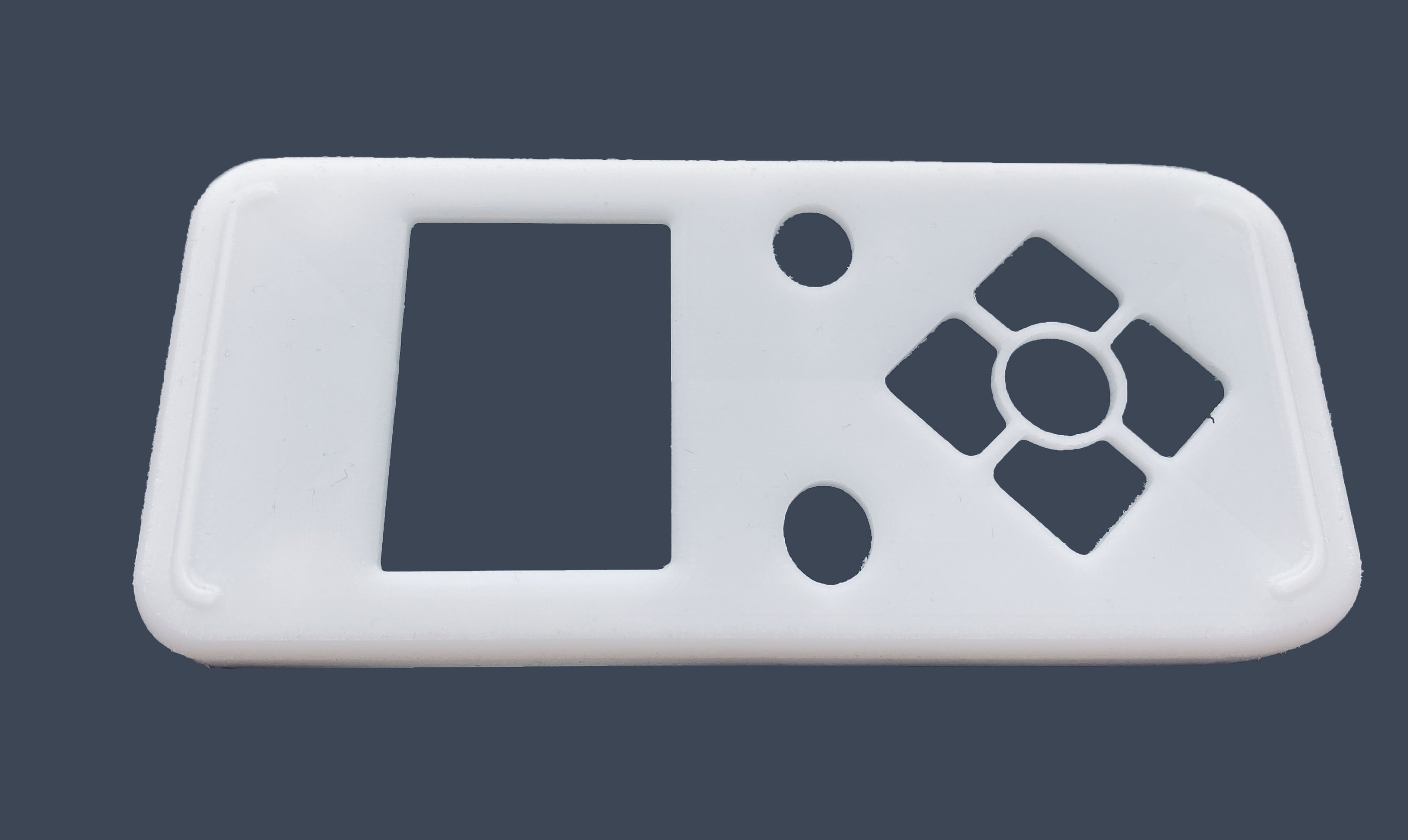

Designed for classrooms, educational institutions, for workshop refinement of parts, for experimental laboratories, small / medium / large industries and private workshops. Precision manufacturing of products for advertising equipment (milling, engraving, cutting), relief technology (coins, medals, stamps), engraving equipment (plates, cups), industrial engraving (plates, labels, warning boards), electronics (front panels, electrical cabinet signatures) , printed circuit boards, cases), modeling (architecture, hobbies), making master models, manufacturing products from materials: glass, plexiglass, FR4, fiberglass, plastic, model plastic, gypsum, carbon, non-ferrous metals (aluminum, duralumin, etc.), furniture production (particleboard, chipboard, MDF, Plywood, Solid, etc.), parquet, art parquet, 3d paintings and decors, “moldings”, wooden toys, stone art products ( paintings, decoration decors, product elements, fireplaces, etc.) Non-ferrous metal and steel work is possible: engraving, drilling, countersink, cutting, marking, cutting, etc. (request cutting conditions and tools from the equipment manufacturer). The package includes the machine tool unit, P.O. GEMMa-3D.

Automation is a key prerequisite for digital production. Each machine of ELBRAS LLC can be turned into a flexible production system by retrofitting with standard automation equipment or automation tools according to customer specifications:

- Fourth axis (A), cartridge Ø80 mm. + tailstock, for rotation of the workpiece 360 degrees.

- Machine control panel

- Licensed P.O .: Geometric modeling and processing programming system for CNC machines GeMMa-4D Professional 1x1 + tech. Support.

- Preparation for aspiration.

The operating system of the CNC machine Linux OS is a CNC device based on the GNU Linux operating system, designed for complex high-performance solutions of the engraving-drilling-milling group. It is a device that allows programmatically generating steps in case of control according to the STEP-DIR-ENABLE type and supports working with industrial boards with hardware G-code processing.

| Clearance | |

|---|---|

| Max. X-axis travel | 15,8 in |

| Max. Y-axis travel | 11,8 in |

| Max. Z-axis travel | 5,5 in |

| Table dimensions | |

| Max. table load | 99 lbs |

| Table length | 15,8 in. |

| Table width | 11,8 in. |

| Volume | |

| Machine length | 31,1 in. |

| Machine width | 30,3 in. |

| Machine height | 31,1 in. |

| Total weight | |

| Total weight | 342 lbs |

| AC Requirements | |

| Mains voltage | 220 V |

| AC frequency | 50 Hz |