APX-60

Highlights

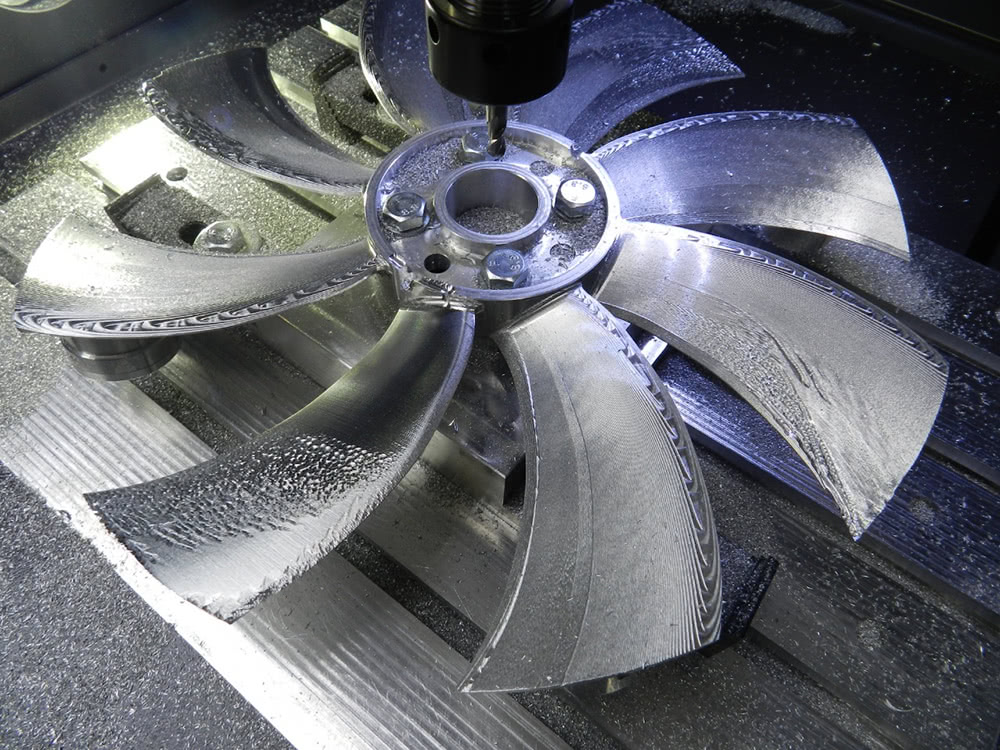

3 axis high performance machining

- Stable design with a work table made of material B95-St

- Mounting the workpiece to the desktop T-mod. groove 11 x 19 mm.

- The maximum speed of movement is 150 mm / sec.

- The machine bed and stand are made in accordance with GOST 12.2.009-099 from St3 / St45 materials up to 20.0 mm thick, annealed, vibration-stress relieved, landing on the bed are made by planing, milling and grinding “in one set”, the drive to the desktop along the Y axis.

Spindles

- 5.5 kW spindle, ER20, 18,000 rpm as standard

- Spindles with speeds of 12,000 and 15,000 rpm (optional)

- Spindle SGC 3.0 kW ER25, 400 Hz, 4.2 Nm, 380V., 2.0 - 24.0 thous. min.

Accuracy

- Stable design with a work table made of material B95-St

- Guides HGR15 HiWin

- XY DRIVE ball screw 1605

- Z Ball screw drive 1605

- Repeatability 0.052 mm.

Equipment

- Rack BaltSystem NC300.

- Set of collets.

- Set of universal carbide cutters.

- Devices for attaching the workpiece to the desktop.

- Machine zero sensors (Home) on the X, Y, Z axes.

- Installation sensor Z coordinates TOOL SENSOR.

- Keys for installation \ removal of the working tool.

- Licensed P.O .: Geometric modeling and processing programming system for CNC machines GeMMa-3D Proma1x1.

- Additional illumination of the "processing zone" of the machine.

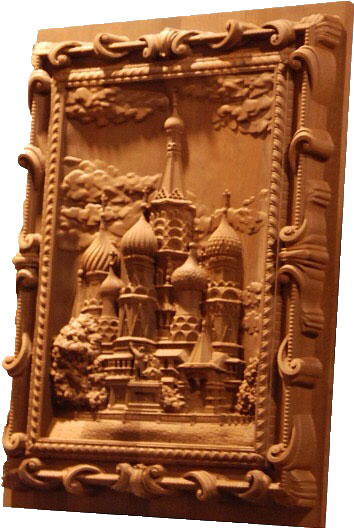

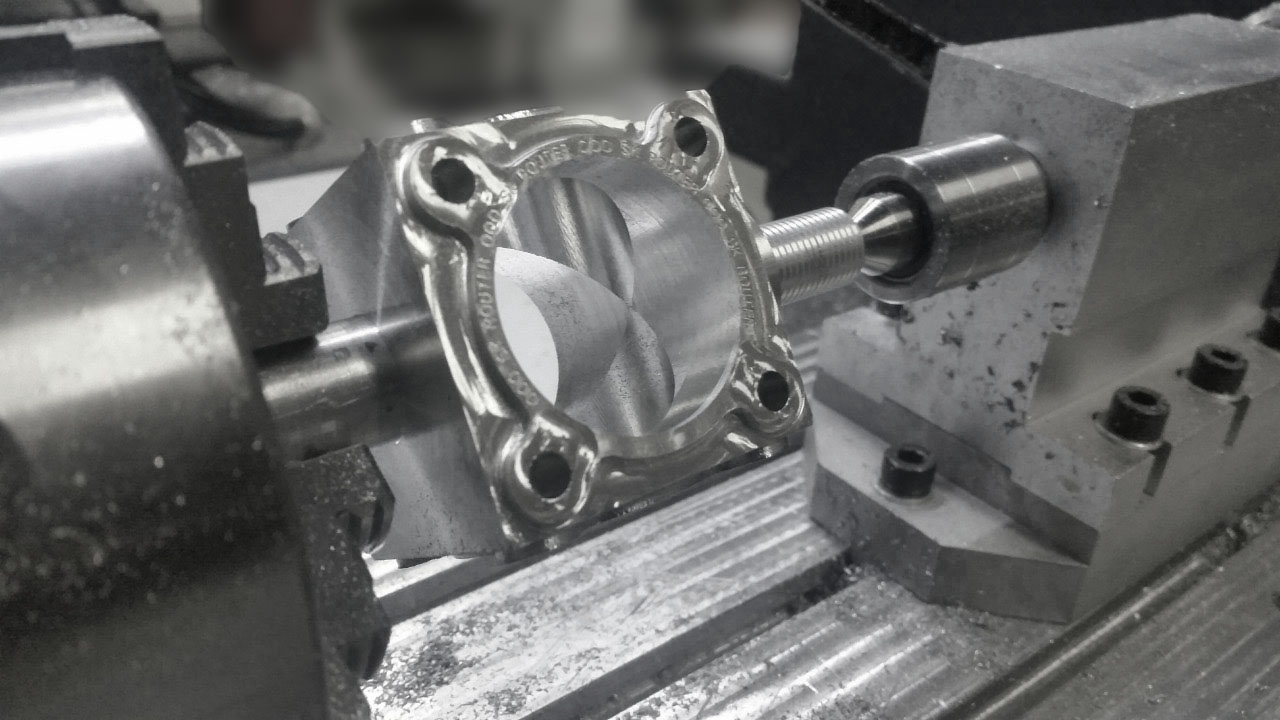

Sample applications

Designed for industries where rigidity and vibration resistance of equipment are required when machining complex parts, complex surfaces, dies, punches, precision mechanics, clichés, dies, molds, profiling rollers of complex shape, master models, rolling dies, dies, dies, complex hole punch dies , die-cutting and perforating dies with a complex configuration of working parts.

Automation

Automation is a key prerequisite for digital production. Each machine of ELBRAS LLC can be turned into a flexible production system by retrofitting with standard automation equipment or automation tools according to customer specifications:

- Fourth rotary axis A, rotation angle + -360 gr. Three-jaw chuck Ø125 mm. . + tailstock.

- Licensed P.O .: Geometric modeling and processing programming system for CNC machines GeMMa-4D Professional 1x1 + tech. Support

- SGC 5.5 kW, VT 30 / ER25, 600 Hz, 9.1 Nm, 4 poles, 380 V., 6.0 - 24.0 thousand rpm., Liquid cooling., Quick change: up to six tools, a magazine with an automatically sliding cover.

- SGC 6.4 kW, VT 30 / ER32, 600 Hz, 12.1 Nm, 8 pole, 380V., 2.0 - 12.0 thousand rpm., Liquid cooling., Quick change: up to six tools, thread-cutting (encoder), shop with automatically sliding the lid.

- Set of polished ballscrews for Hiwin R16-05-0.023 screws + FSI nut 25-05-0.023 on the X, Y, Z axis. (Repeatability - 23 μm / 300 mm)

- Machine vision: binding the workpiece to the desktop, with the output of the tool "to zero"; determination of the angle of the workpiece, the center finder of the hole and the group holes, optical "eye".

- Cabinet of the machine on the bed, with sliding doors + coolant

- ЦС (Central lubrication of guides and ballscrews) on the X, Y, Z axis

- Preparation for aspiration.

Specification

| Clearance | |

|---|---|

| Max. X-axis travel | 23,6 in |

| Max. Y-axis travel | 15,8 in |

| Max. Z-axis travel | 9,8 in |

| Table dimensions | |

| Max. table load | 220 lbs |

| Table length | 23,6 in. |

| Table width | 15,8 in. |

| Volume | |

| Machine length | 55,1 in. |

| Machine width | 39,4 in. |

| Machine height | 49,2 in. |

| Total weight | |

| Total weight | 1 003 lbs |

| AC Requirements | |

| Mains voltage | 220 V |

| AC frequency | 50 Hz |